Frequently asked Questions

- low pressure system (2.5-6kgf/cm2)

This type is the cheapest Disadvantage: surrounding objects get wet.

- medium pressure system (about 15 kgf/cm2)

These systems already require a booster pump. This is a good alternative to high pressure systems. Great for climates with hot and dry air.

- High pressure system (up to 100 kgf/cm2)

The most preferred type, because produces quality

The timer is the only device for changing the operating mode of the fogging system. The timer, by changing the operating time and pause, allows you to significantly expand the temperature and humidity range of the fog cooling system. For example: in the morning the air temperature is still not too high, but it is already getting hot, the fogging is too dense and excessive humidification is obtained, the fog cooling system without a timer will have to be turned off, but if your "outdoor air conditioner" is equipped with a timer, you can set the operating and pause times and continue to enjoy the established pleasant microclimate. The same can be said about hot, but cloudy days with high humidity.

This is not true, since street air conditioning systems have a very small water intake, even with the smallest water leak, which appears when the nozzle cracks and breaks, the pressure in the system drops with lightning speed, as a result of which the nozzle cannot fly anywhere, especially someone injure.

This is not so, even if hot fine dust is sprayed at low air temperatures, since hot water needs much less energy for a phase transition and the air is quite dry, the water will still evaporate, which will lead to cooling, or at a very low temperature to crystallization i.e. it will snow. But one thing is for sure, the high pressure pump will fail very quickly, since the plunger block is cooled by water passing through it, and if hot water is supplied, the pump will overheat and break.

Control is carried out both manually and automatically using the controller.

In addition to the control unit (a pump is connected to it), the controller includes humidity sensors (hygrometers), compare the readings of air humidity with the required values (entered manually ) and control the operation of the pump.

The cyclic timer (time relay) allows you to set the necessary intervals for equipment operation: by hours, days, phases of the day. The user himself regulates the operation in cycles or in the work-pause mode.

In addition, the humidity sensor works on the principle of a thermostat. Fogging equipment can start when a certain lower limit of air humidity is reached and stop working as soon as the desired upper bar is reached. For complex tasks, a combined set of control sensors is used.

• significant decrease in air temperature during the hot season;

• increase in air humidity and creation of a comfortable microclimate;

• increase in aesthetic appeal and exclusivity of the site;

• increase in client flow in public institutions;

• dryness of the ground surface during and after operation of the system (systems with nozzle valves prevent water from flowing through the lower nozzles); br>• reduced irrigation costs;

• increased productivity of the workflow in production.

When salt plugs form on the nozzles, they must be cleaned:

1. Disassemble and place the nozzles in a 5% solution of citric or acetic acid for 24 hours.

2. Blow out with compressed air and assemble the nozzles.

Do not allow the nozzles to dry out.

If the humidifier does not work for a long time, it is recommended to unscrew the nozzles and store them in clean water.

How long your mist system will last depends on the quality of the water. The cleaner and softer the water, the better for the equipment. Water treatment is carried out using special membrane filters, chemicals and electromagnetic softeners. The last method is the most effective and profitable.

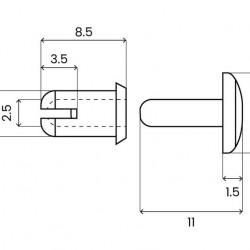

The nozzles spray water, and the higher the pressure, the finer the dispersion of the mist.

The spray of water is carried out in the form:

- fine cloud (most efficient),

- hollow cone,

- uniform solid beam (least efficient way).

fine mist, the particles of which can evaporate instantly.

It consists of periodic cleaning of nozzles and filters, in addition, the pump must be checked annually. The inspection includes changing filters and oil. Filters may need to be replaced after 500 hours of operation. In the conditions of the Ukrainian winter, the system is subject to conservation.

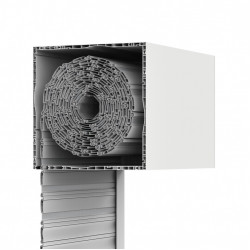

Misting can be carried out in two ways: through nozzles or through fans with built-in nozzles.

The first option is a linear system with nozzles that are equipped with anti-drip valves. This prevents the mist from collecting into droplets when the water pressure drops. Its main advantage is ease of installation and customization.

The second option will be indispensable for places where there is no natural air movement; the water cloud is evenly sprayed over the entire cooling object. Fans can be placed on walls, ceilings, or structural frames.