Share

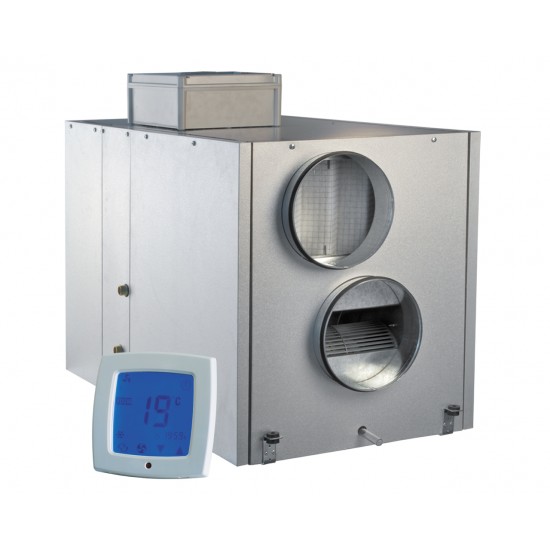

The supply and exhaust unit Vents VUT 1000 VG with a water heater is a completely finished ventilation unit that provides filtration, supply of fresh air to the premises and removal of contaminated air. In this case, the heat of the exhaust air is transferred to the supply air through a plate recuperator; for additional heating, a water heater is used, to which hot water is supplied from the boiler. Nominal capacity1100 m3/h. The unit is designed for connection to round air ducts with a nominal diameter of 250 mm.

The unit is supplied with an automation system and is ready for operation. To regulate the water flow through the water heater, you can use the USVK mixing unit (supplied separately) or any other circulation pump with a three-way valve with the required characteristics.

House

The body is made of aluminum-zinc steel with internal heat and sound insulation made of 25 mm thick mineral wool.

Filter

To filter supply and exhaust air, the unit has two built-in filters with a cleaning degree of G4 (exhaust) and F7 (supply).

Fans

The units are equipped with supply and exhaust double-suction centrifugal fans with forward-curved blades and a built-in protection thermostat with automatic restart. Electric motors and impellers are dynamically balanced in two planes. Rolling ball bearings of electric motors do not require maintenance, the service life is at least 40,000 hours.

Recuperator

The installations use highly efficient cross-current recuperators made of aluminum plates. Under the recuperator block there is a tray for collecting and discharging condensate.

Heater

To operate the air handling unit at low outside temperatures, a water heater is installed. If using heat recovery it is not possible to achieve the set value of the supply air temperature, the heater automatically turns on and heats the air entering the room.

Control and automation

The installation is equipped with a built-in automation system and a multifunctional control panel with a graphic indicator. The standard installation kit includes a 10 m long wire for connecting to the remote control. To prevent the recuperator from freezing, electronic anti-freeze protection is used using a bypass and a heater. Its essence is that, based on the temperature sensor, the bypass damper opens and all the supply air passes past the recuperator through the bypass channel. During the defrosting period of the recuperator, the supply air is heated to the required temperature in the heater. During defrosting, warm exhaust air warms up the recuperator. Then the damper closes the bypass, the heater turns off, the supply air again passes and is heated through the recuperator, and the entire installation operates as usual.

Control and protection functions of VUT VG

- turning on and off the installation,

- control of the supply air temperature by influencing the drive of a three-way valve that regulates the supply coolant into the liquid heater,

- protection of the liquid heater from freezing (using the air temperature sensor after the heater and the return coolant temperature sensor),

- control of the electric drive of the recuperator bypass valve, < li> control and monitoring of the operation of an external circulation pump installed on the coolant supply line to the liquid heater,

- protection of the heat exchanger from icing,

- control and monitoring of the operation of the supply and exhaust fans,< /li>

- control of filter contamination (by the number of operating hours),

- control of electric drives of external air valves (supply and exhaust).

The air handling unit is equipped with a remote control a control panel that provides:

- turning on/off the ventilation unit,

- setting the required air flow rate,

- setting the required supply air temperature,

- display of room temperature.

Installation

The air handling unit is mounted on the floor, suspended from the ceiling using a mounting bracket with a vibration insert, or mounted on the wall using brackets. The installation can be placed both in auxiliary rooms and in the main ones (behind a suspended ceiling, in a niche or in an open way). It can only be installed in such a position as to ensure collection and drainage of condensate. Access for service and filter cleaning is from the side panels.

Specifications

| Parameter | Value |

| Voltage, V | 230 |

| Current frequency, Hz | 50 |

| Maximum fan power, W | 2x410 |

| Total power of the installation, W | 820 |

| Total current, A | 3.6 |

| Productivity, m3/h | 1100 |

| Rotation speed, min-1 | 1850 |

| Noise level at a distance of 3 m, dB(A) | 60 |

| Maximum temperature of transported air, C < /td> | -25....+40 |

| Weight, kg | 88 |

| < strong>Size of connected air duct, mm | 250 |

Dimensions

| Dimensions | D | B | B1 | B2 | B3 | H | H1 | H2 | H3 | L | L1 | L2 |

| mm | 249 | 613 | 460 | 306 | 386 | 698 | 832 | 154 | 280 | 1071 | 1117 | 1171 |

Diagram

Documentation

VUT VG installation passport

Manual for the air handling unit automation system

| Characteristic | |

| Type of heater | Water |

| Efficiency | 1100 cubic meters/hour |

| Duct diameter | 250 mm |

The product will be manufactured after making a payment or a 50% advance payment.

Online payment methods: Bizum, Apple Pay, Mastercard, Visa.

For payments to the bank account of VIP Ventanas SL company: SWIFT, SEPA.

It is possible to make the payment without VAT if the product is delivered outside of Spain.

Delivery is carried out by the company's own transportation or delivery service.