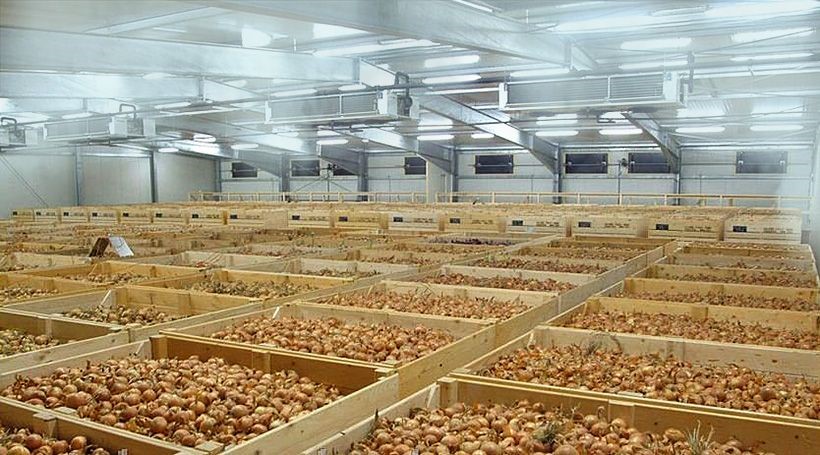

The use of misting systems for storing vegetables and fruits in warehouses and industrial refrigerators

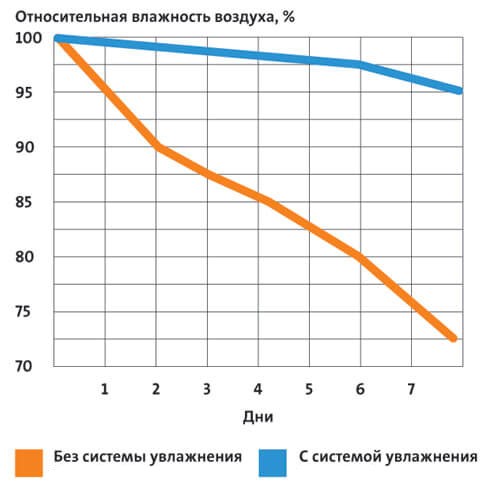

The maintenance of the required level of air humidity has a great impact on the safety of vegetables and fruits in warehouses and industrial refrigerators. With low air humidity, increased evaporation of water occurs. As a result, fruits and vegetables lose their juiciness and freshness, and their mass decreases.

When storing vegetables, fruits and other fresh products, it is necessary to maintain a certain microclimate in the warehouses. Therefore, it is recommended to maintain the humidity in the room where the fruits are stored, in the range of 85-95%. The system of postcooling and humidification by fog formation fully optimizes this process.

Tasks solved by misting systems during cooling and humidification of vegetable storages:

1. Reduction of drying and, as a result, reduction of weight loss of products

2. Fresh and juicy appearance of stored vegetables and fruits

3. Prolongation of the period of preservation and freshness of the product

4. Reducing the volume of illiquid goods

5. Facilitating the ripening process of some types of fruits

6. Control of the spread of odors

7. Increasing your profit due to the above points

What is the misting system for vegetable storages?

For humidification and coolingpressure, less often – low pressure systems (without the use of pumps) The general scheme is given below misting systems for vegetable storages

The misting system periodically sprays the smallest drops of water onto the product, usually for 1 to 5 seconds every 15 minutes. Due to their miniature size, these water droplets evaporate without soaking them, maintaining the necessary humidity and air temperature, reducing dehydration and preserving the weight and condition of the product.

The complete set of the high-pressure misting system includes:

- A pump capable of delivering from 25 to 75 bar (high pressure pump);

- High pressure hose system (100 bar);

- Fine-dispersed nozzles (from 0.15 to 1);

- Fittings;

- Water filters on the supply water supply;

- A fan that dispels fog (if necessary);

- The control unit of the fog generation system;

- High pressure ball valves;

- Drainage valve – prevents stagnation of water;

- Fastening clamps, etc. accessories according to the project.

Unfortunately, there are only general recommendations when designing fog generation systems. The exact calculations depend on specific factors: warehouse area, ventilation, loading, etc. Therefore, the time and number of components of the fog system will be determined individually for your object, depending on the goals and the data.

The misting system solves the issue of creating and maintaining the necessary humidity level in warehouses and refrigerators. As a result, the "shrinkage" of vegetables and fruits is reduced to 1-2%.

The combination of low temperature and high humidity creates optimal conditions for preserving vegetables and fruits for a long time in warehouses and other places.

Leave a Comment