Combating dust and odors in recycling with misting systems

Suppression of dust and nuisance gases by fogging systems in the processing and sorting of garbage and solid waste is a necessary solution today. Dust is generated in the process of recycling, transshipment, unloading, crushing and other processes of processing household and industrial waste.

All processes associated with waste processing generate a lot of harmful dust and gases due to decomposition, which leads to a critical general sanitary state of the environment. Because of this, the productivity of the staff decreases, and occupational diseases of the workers also occur.

The elimination of dust and unpleasant odors from the air is mandatory according to the technology for such processes at the enterprise as: recycling of construction waste, recycling of waste paper, recycling of plastic and polyethylene, solid industrial waste, glass, household waste and other waste.

We all know that the most unpleasant odors come from landfills and recycling plants. People living near such farms know firsthand how unbearable the smell from these facilities can be. This poisons their lives, undermines their health and leads to numerous complaints about enterprises, accompanied by scandals and negative mentions in the media.

The most cost-effective, and one might say the only way to combat dust and gases released into the atmosphere, are high-pressure water mist generation systems.

The basis of this method of dealing with dust and odors is water spraying. To date, this method has become the most effective not only from the point of view of ecology, but also the only possible one. This is due to the fact that traditional aspiration systems are not adapted to work in open spaces or rooms where there is a constant supply of outside air.

From a technical point of view, fogging systems are designed in such a way as to operate in a well-defined place and be as efficient as possible. The direction of the sprayed particles of pure water or water with additives can be adjusted both in range and in the radius of space capture. Here it is very important to arrange the nozzles at an optimal distance from each other so that there are no so-called blind or uncovered zones. Indeed, unlike cooling, to eliminate the smell, the coverage of the perimeter surface must be complete. This is necessary because under the weight of the smallest particles of water, the odor-causing molecules settle on the ground or other surfaces.

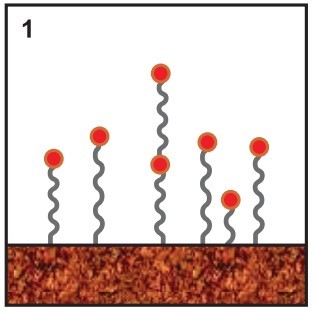

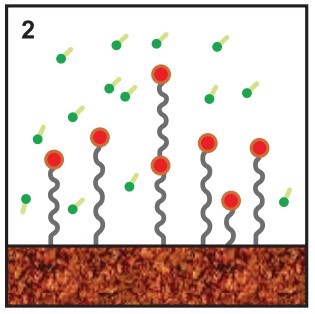

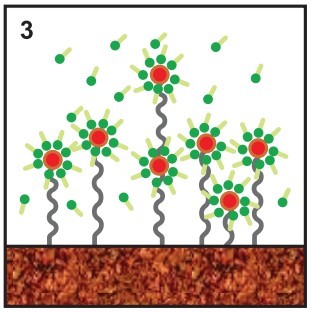

ODOR CONTROL PROCESS

1.Odors in the environment caused by chemical or biological processes.

2.Millions of ultra-fine droplets are sprayed into the environment.

3.The neutralizer droplets cluster around the odorous gas, eliminating it.

In addition to mechanical impact, special substances can be added to the water that will neutralize unpleasant odors. In this case, the operation of the system may not be constant, but periodic. For these purposes, it is not at all necessary to use chemical solutions, natural aromatic oils with antiseptic, antiparasitic properties help here with high efficiency, and their pungent smell repels pests and effectively fights unpleasant odors. At the same time, for a person, the smell of tea tree, pine or eucalyptus is not harmful and unpleasant.

The installation of a mist system in processing plants solves the following tasks:

· Reduce harmful dust as well as gas exposure. This is due to the dust suppression effect inherent in the operation of the systems, which traps floating dust and substances in the air.

· Increased productivity. The productivity of personnel is growing, the percentage of morbidity caused by harmful conditions is decreasing.

Leave a Comment